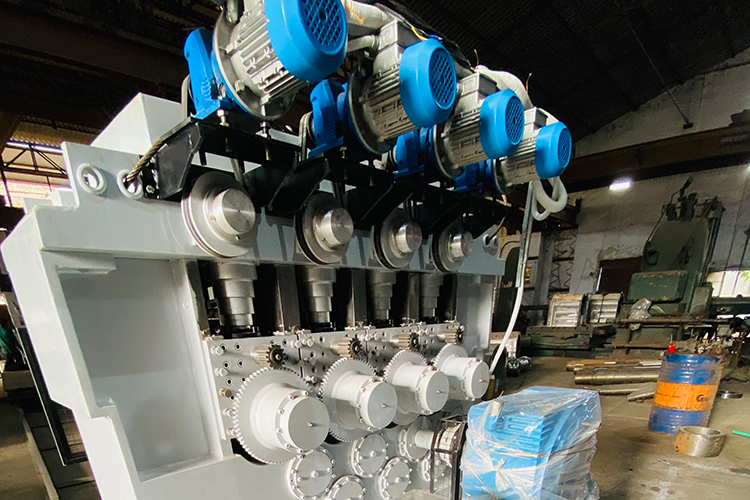

Design

Fabrications and Consultant Engineers are leading manufacturer

and supplier of wide range of Section Straightening Machines in India. They are most

suitable for straightening of curled, out stretched, or forced out ferrous or

nonferrous metal products like angles, channels, rounds, beams, rebars etc.

- The machines are arranged skilfully to give easy, accurate, convenient and

lasting services.

- With the help of these machines, one can straighten the tiny sections as

well.

- These machines are inclusive of bearings, rolls, frame, adjustment, and drive

tools which are manufactured precisely using the best quality stainless

steel.

- These straightening machines are manufactured using the mild steel plates to

strengthen the body, which has to carry the gears to run the rolls. The steel

plates used are of adequate thickness with outer body lining of same plates. The

reduction gear box is fitted on the frame of the machine. It is designed in such

a way that in straightening process the product remains in contact with the

rollers of the machine.

For Channel Straightening Machine, the offered range

is fabricated using optimum quality raw material, which is obtained from reliable

and official vendors of the industry. Moreover, the provided range is broadly

appreciated and acclaimed among our clients for its superb performance, high

efficiency, elevated durability and reliability. The professionals employ simple

machinery and high technology in accordance with the industry laid standards and

norms. Besides, there has been an assurance to test the complete range on diverse

parameters to maintain its accuracy throughout the whole production process.

Design Fabrications and Consultant Engineers, one of

best Channel Straightening Machines

Manufacturer in India started the journey of serving clients

not only with a motive of making profiles, but also good customer relationships. Our

professionals believe in taking care of our clients and their years of expertise and

experience has made us efficient enough to serve our customers with qualitative

products. We understand client’s need that is why equipped ourselves with modern

machines to meet client’s requirements efficiently. Our main strength is

synchronized team work, latest tools equipped with latest technologies and

continuous reformation in every process. We serve our clients with the qualitative

products which bring them success in their business. The products offered by us are

appreciated for the features like high quality and long-term efficiency. Our

complete product array is manufactured

under the strict supervision of our experienced

engineers as per the defined industry standards. Each and every person in our team

is committed to provide superlative products and excellent customer care service.

Buyers will see the difference by themselves. The professionals of our team possess

huge experience in their respective domain and work in close-coordination with the

novel technology to meet the emerging requirements of the market. These

professionals make the best possible use of the available resources that also assist

in offering a cost-effective range of machines.

Advantages of Channel Straightening Machines-

- Simple to lead

- Amazing execution

- Easy to handle and beneficial

- Long working life

- It is straight Girders, Channels of all size.

- It can be customized according to the needs.

- With the support and dedication of skilled workforce, Channel Straightening

Machine Manufacturers present an impeccable quality range of Metal Angle

Straightening Machine. The machines are manufactured in such a way that it

consumes less power and provides world class performance to the end user.

- Design Fabrication and Consultant Engineers share expertise in Section

Straightening Machine, Angle Straightening Machine, Transmission Line Tower,

Rolling Mill Machinery and Rolling Mill Straightening Equipment, possessing of

hardcore systems based on state of art technology with excellence performance.

- It has well-furnished equipment and best platform to design and redesign the

machines as per the requirement of customer and are in a process to develop more

and more accuracy works machine with less error or error-less system to meet the

requirement. They are the versatile manufacturer of the section straightening

machine in India. Prompt time delivery, customer satisfaction and accuracy are

our motto.

- It has been a recognised name in this field for years and is constantly working

for the trust which it has built in the past. They are also serving clients

overseas for a long time which has created a distinguished image of the Design

Fabrication and Consultant Engineer in the market.

The construction of machines for straightening of various straightening applications

is an integral part of core competence. At production sites of Channel Straightening Machines

Manufacturer in India, there has been a constant development

and designing of novel systems, control concepts and machine tools so that

manufacturing companies can offer customers an optimised solution. As a specialist

with its own design department, the companies possess the necessary competence and

technologies to solve special bending or straightening requirements. In addition to

a high degree of in-house production, the machine is assembled exclusively with

components and parts from selected and long-standing suppliers and dealers.

Special applications such as double straightening

machines, torsion straightening or combined horizontal / vertical straightening

machines belong to numerous projects, which are allowed to realize for the

customers. Increasingly also the automation is provided. Feeding systems and the

processing and automatic straightening according to the motto "fully automatic

straightening" are only a few keywords. It is also possible to develop a machine or

manufacturing process according to the ideas and specifications.

As a specialist, manufacturer and supplier located in

India, the purchase or sale can be made either directly or through dealers. Design

Fabrication and Consultant Engineers straightening machines and bending presses are

also increasingly used by international customers worldwide and are used in many

areas of application for bending or straightening.